Smoothary Industry Solution Pvt. Ltd.

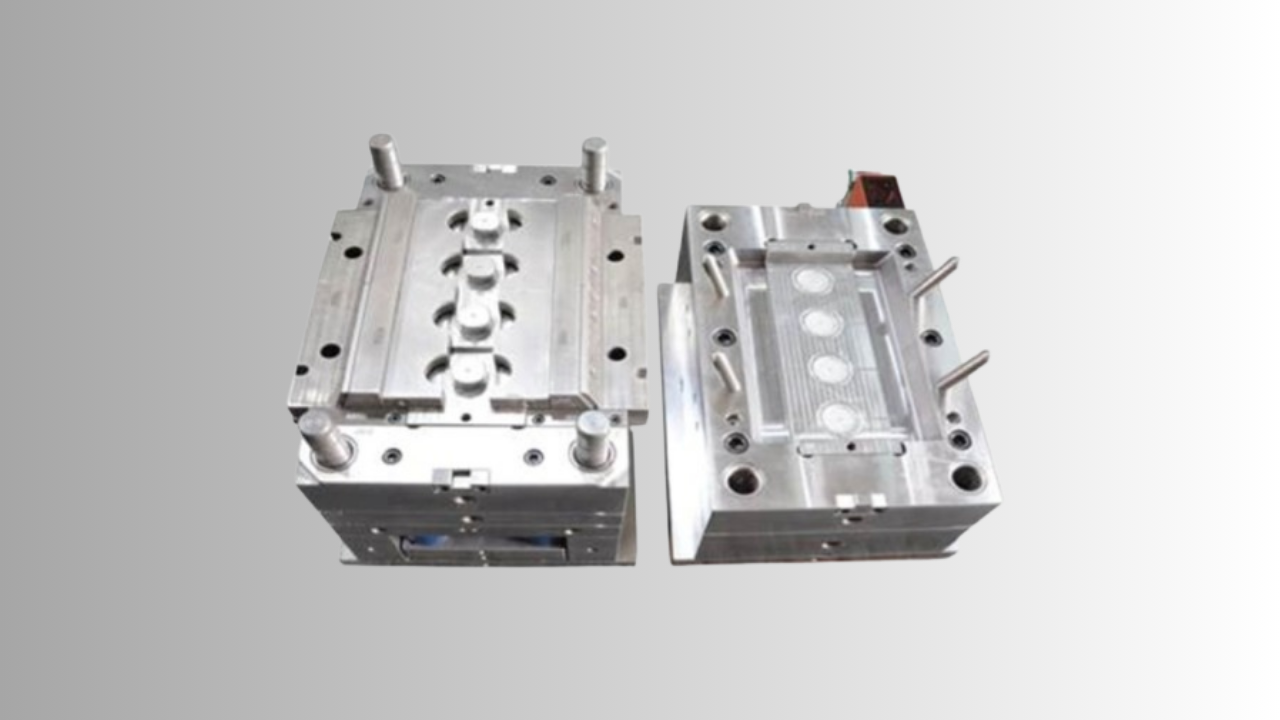

Our die casting division produces precision components with complex geometries, ideal for industries like automotive, electronics, and machinery. We offer:

At Smoothary Industry Solutions Pvt. Ltd., we specialize in aluminum die casting, delivering high-quality, durable, and dimensionally accurate components for a wide range of industries. Our advanced High-Pressure Die Casting (HPDC) facility is equipped to meet the growing demand for lightweight, high-strength aluminum parts with complex geometries and tight tolerances.

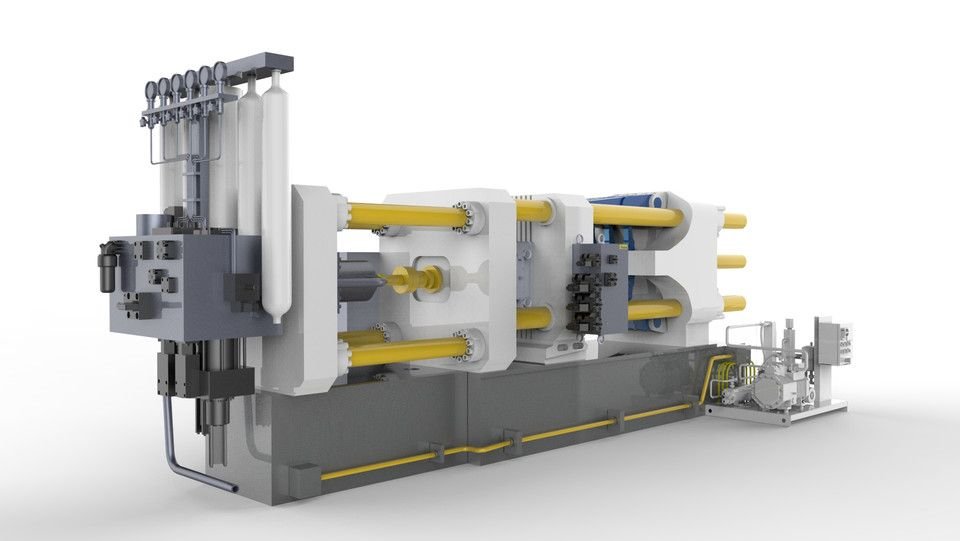

We take pride in using the latest Yizumi HPDC 3 Series die casting machines, ranging from 300, 400, 500, 700, to 900 tons, ensuring flexibility and precision for components of various sizes and specifications. Each machine is integrated with servo sprayers and auto extractors, optimizing efficiency, consistency, and quality across every production cycle.

Our production line incorporates modern technology and advanced automation, allowing us to achieve superior surface finishes, reduced cycle times, and enhanced mechanical properties. By combining modern engineering practices with state-of-the-art machinery, we ensure every component meets international quality standards and customer expectations.

At Smoothary Industry Solutions Pvt. Ltd., we are committed to innovation, precision, and reliability—driving excellence in aluminum die casting for the modern manufacturing world.

Our servo-controlled spray system is designed for precise, consistent, and efficient lubrication and cooling of the die cavity during each cycle.

Features:

Our electric auto extractors provide efficient and reliable part removal from the die, improving cycle time and safety.

Features:

High pressure Die Casting Machines: [ tonnage range from 300T to 900T]

Our die-cast aluminium parts are used across various industries, including:

Engine housings, transmission parts, brackets, wheels

Heat sinks, enclosures, and connectors

Lightweight structural components

Gearboxes, motor housings

Handles, panels, covers, and fittings

Solar panel brackets, wind turbine components

Our die casting process is supported by a robust quality management system, ensuring each part meets the required specifications and standards. Our QA measures include:

We are committed to sustainable manufacturing by integrating aluminium recycling and waste reduction into our die casting operations. Aluminium is 100% recyclable without loss of quality, making it the perfect material for green manufacturing.